The purpose of the company is to maintain balance: “Extremely clean workplace with certification, with zero environmental burden.”

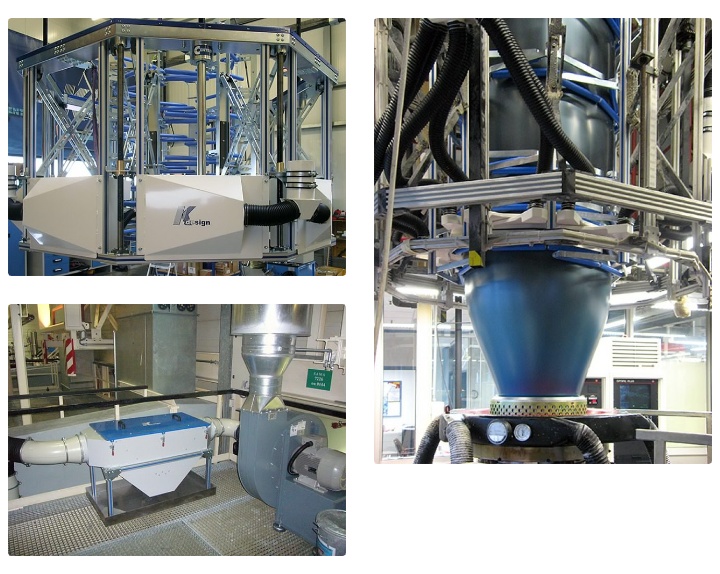

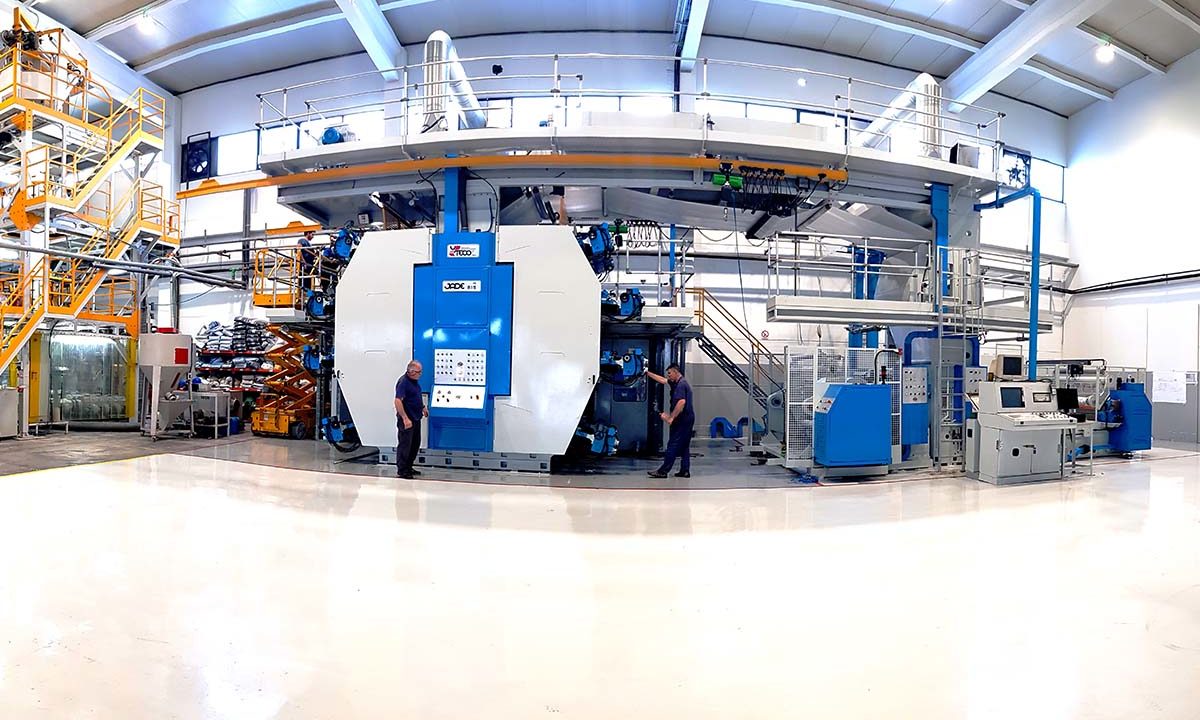

Polyethylene scrap recycling line operation with the ability to produce more than 20 tons per week of regenerated grain. The line has two vacuum stations for the complete absorption and subsequent separation of volatile substances from the printing impressions of our products. The result is, on the one hand, the creation of recycled grains of much better quality and better exploitation, and on the other hand, the retention and collection of harmful substances in the form of liquid.

Polyethylene scrap recycling line operation with the ability to produce more than 20 tons per week of regenerated grain. The line has two vacuum stations for the complete absorption and subsequent separation of volatile substances from the printing impressions of our products. The result is, on the one hand, the creation of recycled grains of much better quality and better exploitation, and on the other hand, the retention and collection of harmful substances in the form of liquid.

Dirty solvent recycling system from printing presses. 90% reusable solvent and 10% solid residue is created available to a certified waste collection company

Oxidation of gaseous oxide fractionation system (RTO). Modern state-of-the-art solvent combustion system that minimizes the emission of harmful volatile hydrocarbons into the environment.

In the extruder section, all new installations have a system for absorbing the monomer-lubricants produced during the processing of polyethylene and collection in special separators.

Continuous upgrade and investment in modern electromechanical equipment achieving a reduction in energy required for the production process through advanced engines driven by inverters

Replacement of industrial lighting in energy efficient modern lamps with low radiation and reduced energy, equal performance.

Design of facilities to maximize the use of natural light

Grouping of finished product deliveries as an additional measure to reduce the energy footprint.

Use of special stainless steel filters / profiles / bag filters in the CLEANROOM CLASS 8 ventilation unit. Use of HEPA filters / bag filters and filters for the CLEANROOM CLASS 7 unit. Energy design, obtaining medium and low voltage energy data, reducing consumption at peak hours, operation of the unit on a 24-hour basis – 7 days / week resulting in the mitigation of the HEDNO network with consequent reduction of pollution – CO2 of the power generation system due to reduction energy consumed.

Study for the use of renewable energy sources (Photovoltaic panels on the roof of the factory)

Exploitation of the produced temperature of the air compressors and the extruders for the heating of the production areas.

Replacement of industrial lighting in energy efficient modern lamps with low radiation and reduced energy, equal performance.

Design of facilities to maximize the use of natural light

Grouping of finished product deliveries as an additional measure to reduce the energy footprint.

Use of special stainless steel filters / profiles / bag filters in the CLEANROOM CLASS 8 ventilation unit. Use of HEPA filters / bag filters and filters for the CLEANROOM CLASS 7 unit. Energy design, obtaining medium and low voltage energy data, reducing consumption at peak hours, operation of the unit on a 24-hour basis – 7 days / week resulting in the mitigation of the HEDNO network with consequent reduction of pollution – CO2 of the power generation system due to reduction energy consumed.

Study for the use of renewable energy sources (Photovoltaic panels on the roof of the factory)

Exploitation of the produced temperature of the air compressors and the extruders for the heating of the production areas.

The Art of Flexible Packaging